Hemp Filter Centrifuge

Supplier: FUYI Machinery

Share to:

Details

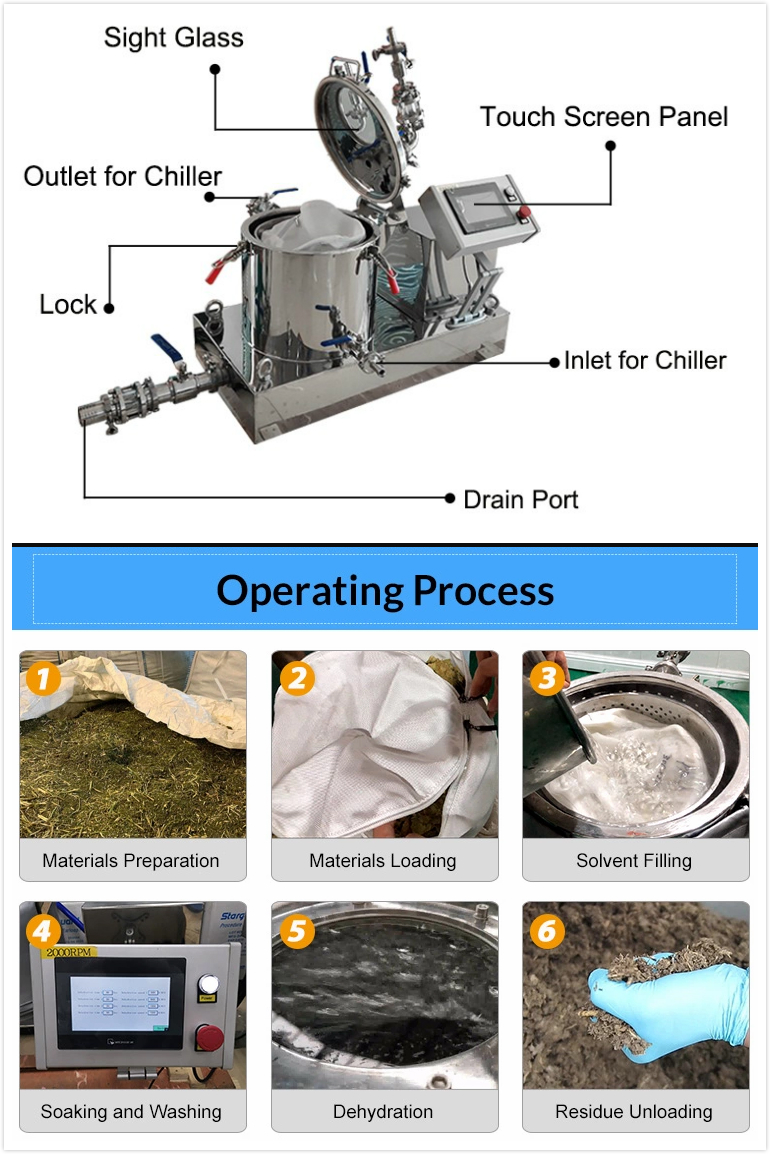

Working principles of hemp centrifuge extractor

FUYI Brand PTD hemp filter centrifuge is to use centrifugal force to accelerate the liquid phase in the solid-liquid mixed liquid out of the rotating drum, and leave the solid phase in the rotating drum, so that the different materials that need to be separated can be accelerated to separate the machine.The operator should fill the filter bag with crushed plant material and places it in the machine. Then, add alcohol until the plant material is submerged. After soaking at low temperature and setting a program to rotate at a low speed in both directions,the active ingredients in the plant are fully extracted. Rotate at high speed and open the bottom discharge valve to discharge the extract.

Technical parameters :

|

Model |

Drum diameter mm |

Drum height (mm) |

Revolving speed |

Motor Power (KW) |

Size (mm) |

Weight (KG) |

|

PTD15 |

300 |

250 |

2000 |

1.1 |

1100*650*1020 |

240 |

|

PTD25 |

300 |

350 |

2000 |

1.5 |

1100*650*1020 |

260 |

|

PTD45 |

450 |

300 |

1500 |

2.2 |

1400*700*1080 |

380 |

|

PTD65 |

450 |

400 |

1500 |

3 |

1400*850*1080 |

410 |

|

PTD115 |

600 |

500 |

1250 |

4 |

1600*1060*1250 |

800 |

|

PTD145 |

600 |

500 |

1250 |

5.5 |

1600*1060*1330 |

820 |

PTD15 Charge per batch around 5Kg(10 pound) Amount of ethanol each time around 30L(8 gallon)

PTD25 Charge per batch around 8Kg(18 pound) Amount of ethanol each time around 40L(11 gallon)

PTD45 Charge per batch around 14kg(30pound) Amount of ethanol each time around 85L(23 gallon)

PTD65 Charge per batch around 20kg(45pound) Amount of ethanol each time around 105L(28 gallon)

PTD115 Charge per batch around 25kg(55pound) Amount of ethanol each time around 175L(47 gallon)

PTD145 Charge per batch around 45kg(100pound) Amount of ethanol each time around 210L (50 gallon)