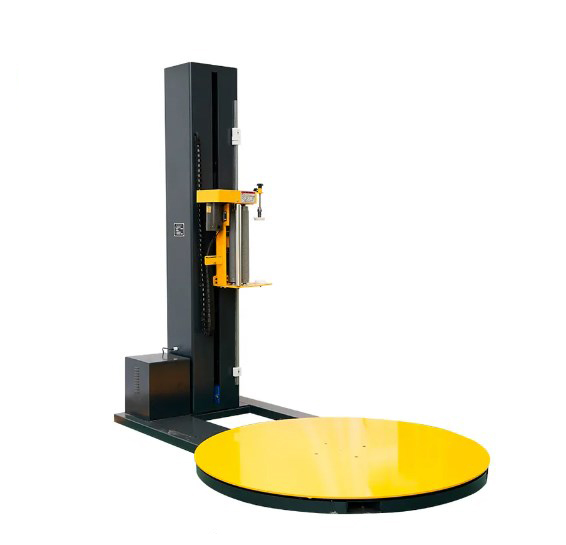

PLC programmable control, winding program optional, various parameters adjustable,

Photoelectric switch automatically senses cargo height

Pre-stretching automatic film feeding mechanism

Rotary slow start, slow stop, automatic reset

The top and bottom winding numbers are individually controlled

Automatic, manual switchable, virtually no routine maintenance required

Turntable drive:

Turntable frequency control 0~12 rpm adjustable;

The turntable is automatically reset;

The turntable is made of pure steel and high wear-resistant material.

Film system:

The membrane frame dynamic pre-stretching mechanism can pre-stretch up to 250%, reducing the amount of film consumption.

The rise and fall speeds of the membrane frame are respectively adjustable.

Film feed speed is adjustable; separate DC motor control.

The top and bottom winding numbers are individually controlled.

The film system follow-up mechanism, a pull.

The film frame is a pure cast aluminum frame, which is light and stable.

Use wear-resistant rubber roller, long service life.

The lifting column is a single chain structure, which is stable and reliable.

Main Technical Parameters

|

Turntable diameter: |

1650mm |

|

Wrapping productivity: |

20-45 pallets/h |

|

Wrapping specification: |

L(500-1200)mm*W(500~1200)mm |

|

After packing size : |

2920x1880x880mm |

|

HS CODE: |

8422400090 |

|

Standard Wrapping height: |

2000mm |

|

Max. turntable loading: |

2000kg |

|

Machine size: |

2920x1650x880mm |

|

Turntable height: |

80mm |

|

Machine weight: |

750kg |

|

Machine power: |

1.5Kw |

|

Supply voltage: |

120V/60HZ, 1 Phase |

|

Turntable speed: |

3~12rpm |

|

Wrapping material: |

LLDPE Stretch Film |

|

Thickness: |

17~35μm |

|

Width: |

500mm( can be customized) |

|

Inner center of film roll: |

76.2mm |

|

Max. film roll diameter: |

250mm |